Overview

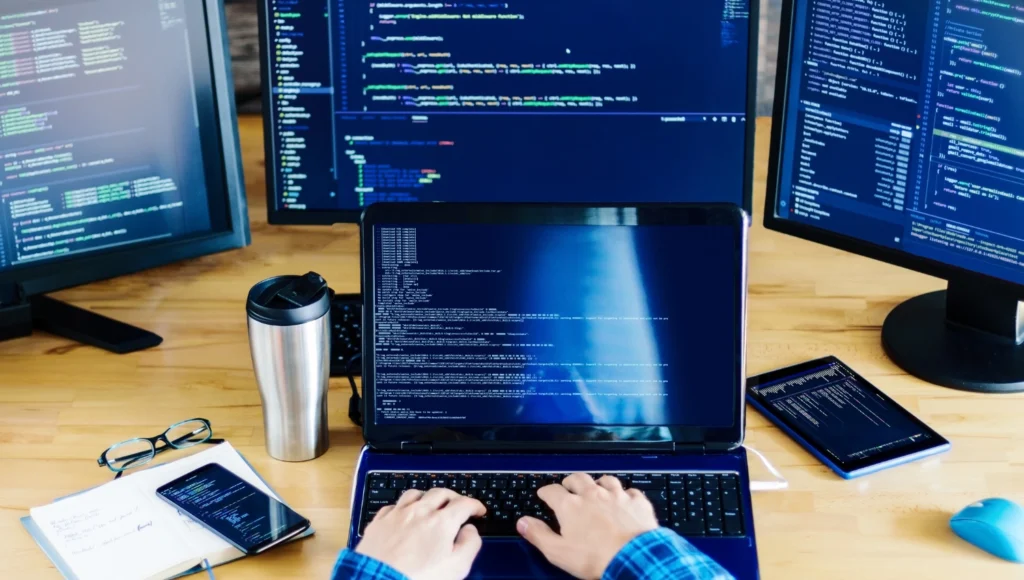

In the dynamic landscape of today’s ever-growing disruptions, industrial manufacturing is at the forefront of embracing new technologies and showcasing a commitment to innovation. These disruptions include challenges from tech-driven entrants, the decoupling of global business operations, and the demand for innovative products to achieve net-zero emissions goals. The industry is also being shaped by shifting consumer preferences, a shortage of skilled labor, and evolving distribution models. To remain competitive, these organizations need to seamlessly integrate new business models and proactively invest in technology for faster adaptation. We offer a diverse multitude of solutions built on Oracle Cloud technologies, enabling manufacturing companies to improve production efficiencies while reducing costs. With our advanced solution offerings, we help manage your complex mix of distribution channels, diverse products, pricing structures, profit margins, and operational processes.

Trinamix deep expertise in Industrial Manufacturing

Component lot allocation algorithm

Audit trail/ changed history tracking

Plan/build instruction

Import from planning systems

Start/slit/trim production optimization

Detailed lot genealogy

Inbuilt adapter for Oracle SCM cloud

Advanced manufacturing and planning master data management

Built on Oracle Analytics Cloud

Supplier Risk Score-Carding

Predictive Insights on OTIF Delivery, Quality, and Yield

Real-time Integration of External Risk with Enterprise Systems

Notify External Risk

Analytical Algorithms to Assess Disruptions and Recommend Efficient Alternates

Integration between SCM Cloud, IOT, Production

Monitoring, AIMFG, IOT Asset Monitoring

Co-development of IoT and SCM integration

Involved in use case development

Own Oracle IOT license to experiment and develop IoT lab

Customer POC and Help in Proof-of-Concept building

Predictive Models and Establish the edge connectivity

Establish Integration between various SaaS and IoT components

Optimal inventory Spending

Guarantee high service levels at lower cost

Governance and Process Optimization

Prediction of OTIF delivery and Optimal Safety Stock sizing

Optimal Safety Stock sizing

Digital Supply Chain Twin

Eliminate Waste and Bottlenecks Across the Network

Multi-echelon Perspective to Enhance the Overall Value

Prescriptive Analytics on Dynamic Adjustments

What if Scenarios and Simulations

Adaptive Demand Driven Approach

Informed Decisions Through Scenario Planning

Success stories

Key Benefits

Enhanced visibility across the entire supply chain for improved transparency

Achieve high service levels with minimal inventory through efficient management

Accelerate time-to-market for products with a focus on speed

Maximize On-time In-Full (OTIF) performance for reliable order fulfillment

Optimize inventory in response to uncertain demand, improving efficiency

Inventory reduction strategy to eliminate excess products, free up warehouse space, save costs, and boost profits

Ready to Unlock Predictable, Data-Driven Manufacturing?

You may also like

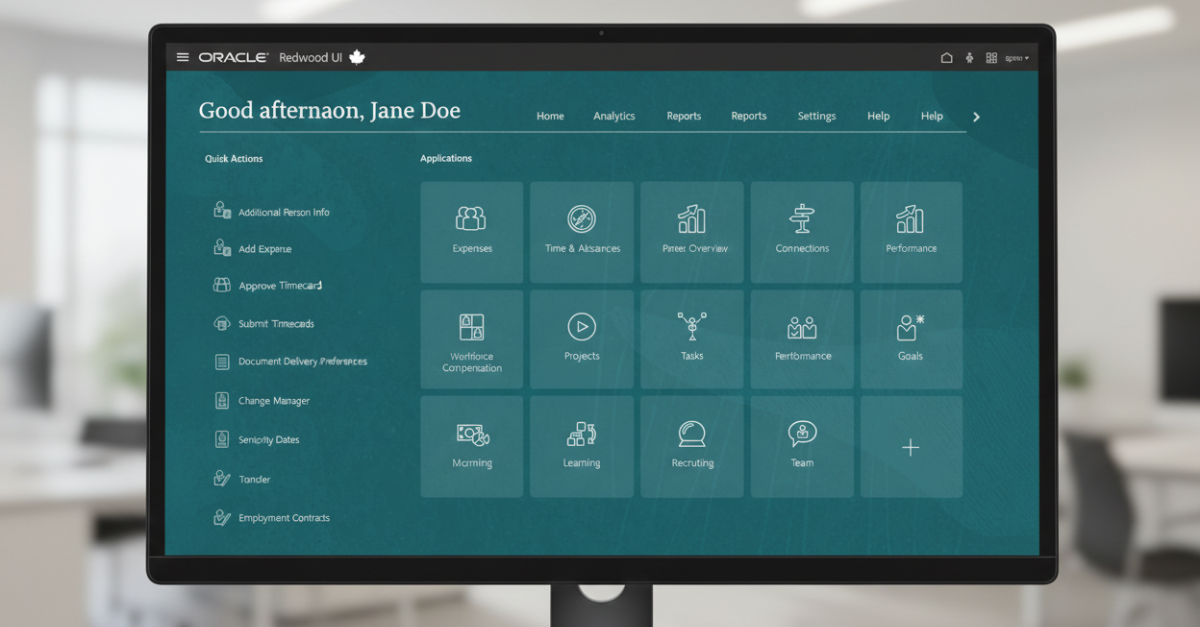

Redwood UI – How It’s Changing and How It Differs from the Previous UI

User experience is no longer just about navigation and screen layouts—it’s about

Understanding Generative AI: What it is and how it works

In today’s fast-evolving digital landscape, Generative AI (GenAI) is no longer just

Inside Oracle AI World 2025: Trinamix Highlights and Takeaways from a Game-Changing Week in AI

Oracle AI World 2025 marked an exciting milestone in Trinamix’s journey to

Extending Oracle Smart Operations: The Emerging Patterns of Cloud MES Adoption

Extending Oracle Smart Operations to Meet Industry-Specific Needs As we continue our

Frequently asked questions

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua…Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua…