Solution Overview

Background

Success Stories

Key Features

For Today and the Future

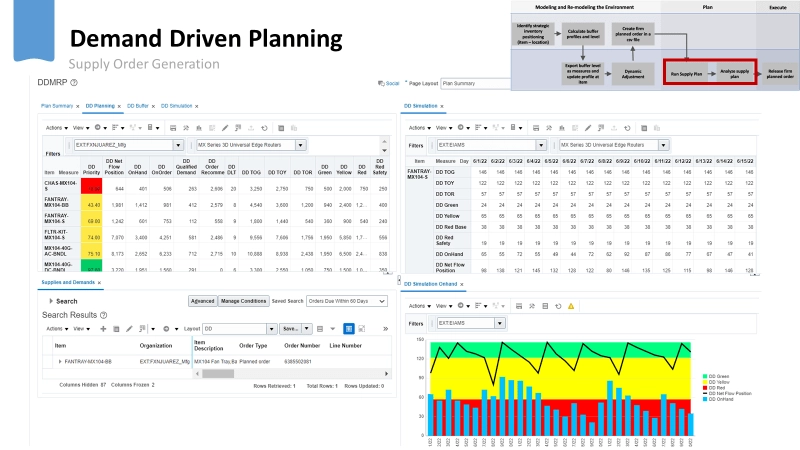

- Provide the adaptive demand-driven approach in an uncertain and volatile world

- Globally scalable for scrambling up growth with supply chains

- Optimization to reduce transportation cost, achieve higher discounts and maximize coverage

- Multi-echelon perspective to enhance the overall value chain

- Collaboration to improve agility, reduce bullwhip effects, and organize supply chains more effectively

- Process management aligning all business processes with organizational strategic goals

CIO/CXO

- Improve service level through automating supply chain management processes

- Synchronize supply with demand to reduce inventories

- Increase output on bottleneck resources to improve revenue

- Incredibly quick in reacting to the demands of modern warfare

- Improve ROI and cash-to-cash cycle

- Unlock the full potential of the supply chain by protecting the flow of information and material

Planners

- Powerful visual indicators highlighting relative priority

- A mapped business playbook for aligning supply chain strategies, priorities, and interdependencies

- What if scenarios and simulations to establish confidence for small changes

- Straightforward and Intuitive solution for a complex problem

Managers

- Make informed decisions through scenario planning, helping identify ranges of potential outcomes and impacts

- Prescriptive analytics on dynamic adjustments

- Eliminate waste and bottlenecks across the network, causing production and shipping delays, high costs, and backlogs of orders

- Monitor and improve performance by tracking various operations and events and identifying the areas for improvement

- Align plans with business strategy to manage their global business environments and gain a competitive advantage

Key Benefits

40%

Inventory reduction to eliminate excess products, free up warehouse space, save money, and increase profits

100%

On-time delivery to keep delivery performance and supply chain efficiency in the organization at par

200%

Inventory turns improvement to eliminate products with lower turnover ratios to improve the company’s inventory turnaround

80%

Lead time improvement to remove unnecessary tasks, waste, and waiting time from different processes

20%

Customer service improvement by exceeding their expectations

8-12 weeks

Fast Implementation with 8-12 weeks typical timeframe

40%

Planner availability to reduce time spent on repetitive planning activities and more time on tactical and strategic decisions

100%

Pasy and Intuitive with color-coded priority and demand-driven approach to provide visibility and prioritize the orders

90%

Obsolescence reduction to remain competitive and profitable while incurring huge capital expenditures when a product or service is outdated

Other Resources

Trinamix Investment Buy

Trinamix Investment Buy is an AI-powered solution designed to empower retailers with a range of functionalities tailored to enhance their operations. With utmost capabilities like inventory optimization and truck optimization, retailers can streamline their supply chain processes and ensure efficient resource utilization.