Trinamix Multi-Echelon Inventory Optimization

Inventory optimization and safety stock planning

Solution Overview

Optimal Safety Stock Sizing

Algorithm optimizes safety stock using simulation of an econometric KPI called 'Marginal Utility of Inventory' against inventory positions

Multi-Echelon Optimization

Algorithm can infer postponement & risk pooling, account for 'disruptions' in demand, supply; flexibility for planners to change

Inventory Entitlement

A mechanism to decompose stock drivers into error, disruptions etc. for planners to focus on right levers; monitoring of inventory drive

Budget Constraint

Genetic Algorithm to optimize inventory holding in constraint environment

Prediction on OTIF Delivery

Correlation with historical data, current & predicted events

Governance & Process Augmentation

Workflows for planners to simulate inventory levels and infer impact on the supply chain

Background

In recent decades, value chains have grown in length and complexity as companies expanded around the world in pursuit of margin improvements. However, the way value chains have shaped with global environmental changes and organizations are subjected to more disruptions with growing frequency. To be resilient against these risk, companies needs to be ready for anything. To be ready, companies needs to optimally place buffer across the supply chain decoupling any variability.

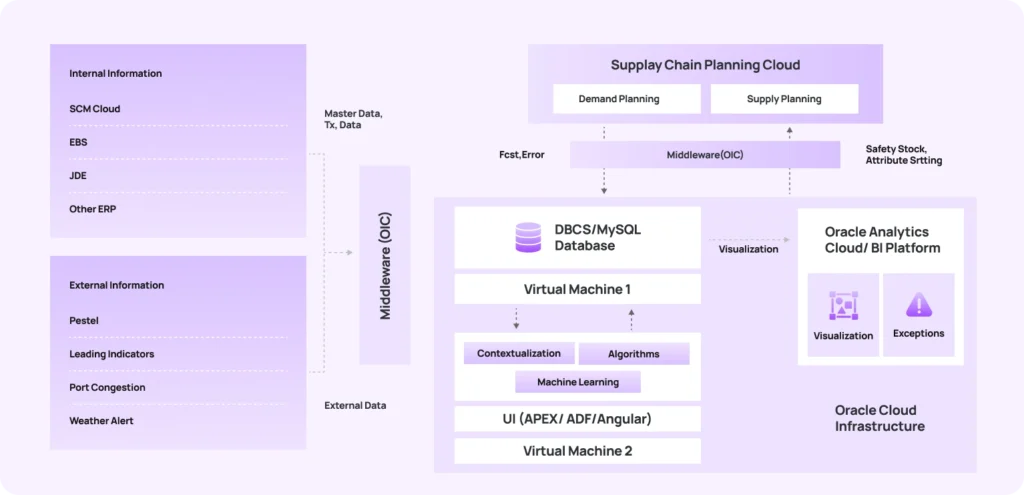

Architecture: Trinamix Resilient Planning (MEIO)

Success Stories

Key Features

Automate planning to increase productivity

Optimal inventory spending

Guarantee high service levels at lowest cost

Position inventory across the network to efficiently meet high customer service level with minimum inventory investment

Master demand uncertainty

Digital supply chain twin

Key Benefits

Free up working capital

Meet high service levels while minimizing inventory

Optimize inventory for uncertain demand

Trinamix’s Multi-Echelon Inventory Optimization is listed on the Oracle Cloud Marketplace.

Other Resources

Trinamix Supply Chain Network Optimization

Trinamix Supply Chain Network Optimization (SNO) provides a comprehensive framework for designing, simulating, and optimizing supply chain networks. It enables organizations to create real-world network models that map suppliers, manufacturing facilities, distribution centers,

Trinamix DDMRP for Planning

Over the last ten years, value chains have grown in length and complexity as companies expanded globally in pursuit of margin improvements.

Frequently Asked Questions

What is Trinamix Multi-Echelon Inventory Optimization (MEIO)?

Trinamix MEIO is a cloud-based solution that helps organizations optimize inventory levels across multiple nodes of the supply chain — from plants and distribution centres to retailers — ensuring the right inventory at the right place and time.

What challenges does Trinamix MEIO solve?

How does Trinamix MEIO improve supply chain efficiency?

How is Trinamix MEIO different from traditional inventory planning?

What are the key benefits of implementing Trinamix MEIO?

- Reduction in total inventory investment

- Improved service levels and on-time fulfilment

- Enhanced forecast accuracy

- Better supply chain visibility and collaboration

Can Trinamix MEIO integrate with existing ERP or SCM systems?

Yes. Trinamix MEIO seamlessly integrates with Oracle Cloud SCM and ERP systems and can also connect with third-party systems like SAP.

Is Trinamix MEIO available on Oracle Cloud Marketplace?

Does Trinamix MEIO leverage AI and advanced analytics?

Absolutely. Trinamix MEIO uses machine learning and predictive analytics to forecast demand variability, simulate scenarios, and recommend optimized stocking strategies.